WanHai Medical’s 100,000-class clean workshop gains another core strength as the intelligent fully automated assembly and inspection line officially begins operation. In fact, the workshop is already equipped with an intelligent fully automated silk-screen printing line. The addition of this new line further enhances the automated production matrix, reshaping the production landscape of pen injectors through technological innovation and setting a new benchmark for automated production in the industry.

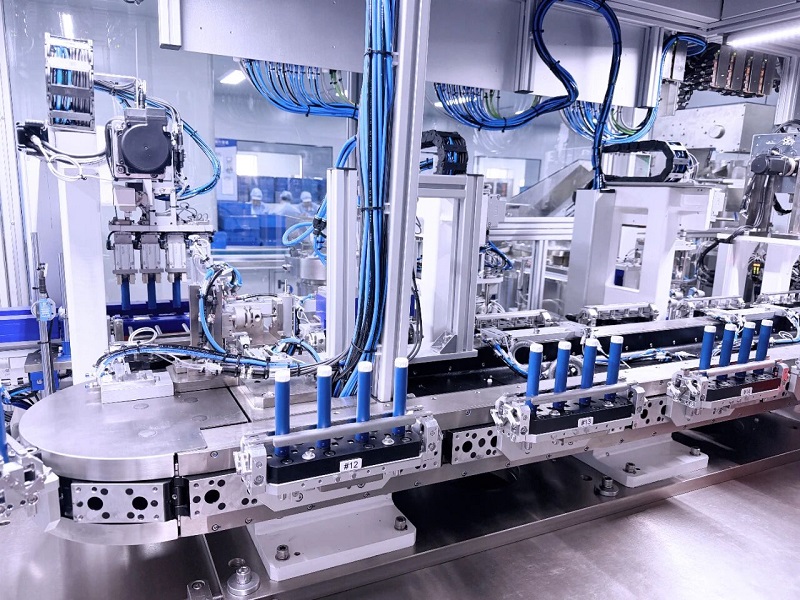

From semi-automated assembly and manual inspection to integrated fully automated assembly and inspection, led by domestically developed fully automated lines, WanHai Medical is steadily advancing towards an unmanned production base.

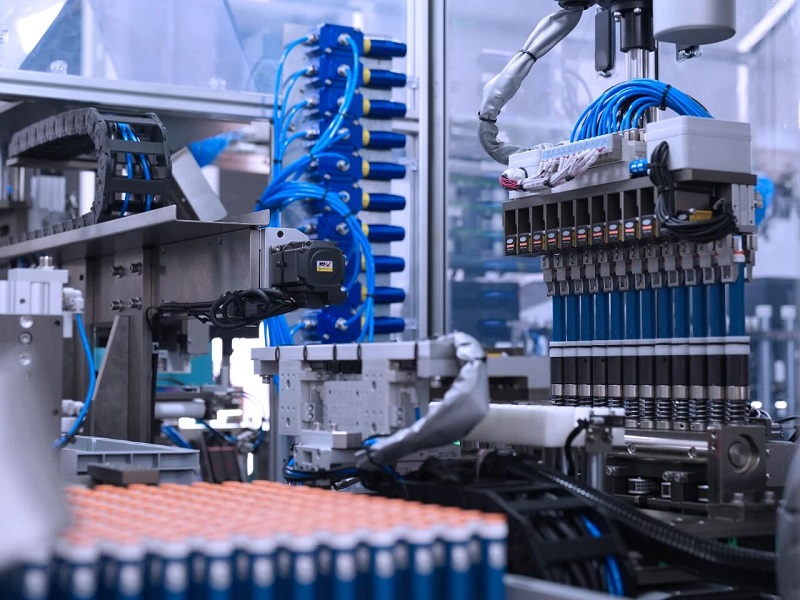

The intelligent fully automated production line, integrating pen injectors assembly and quality inspection, highlights WanHai Medical’s breakthrough progress in production technology.

·Leading Domestic Automation: This assembly line is the first fully automated domestic assembly line, breaking the previous reliance on imported equipment in the domestic market. It represents a breakthrough in the localization of fully automated pen injectors assembly equipment, marking a significant improvement in China’s independent production capabilities in this field.

·Exponential Leap in Production Efficiency: Compared to the previously commonly used semi-automated assembly lines in China, this intelligent production line has increased efficiency by 2-3 times, with a single-line daily output reaching 100,000 units. This leap in efficiency has completely overcome the capacity bottlenecks of traditional production models, laying a solid foundation for large-scale production.

·Intelligent Inspection Ensures Superior Quality: The production line features an ultra-high level of intelligence and integration, incorporating numerous high-precision sensors and visual inspection systems to achieve seamless integration of assembly and inspection. Compared to traditional manual inspection methods, the integrated fully automated assembly and inspection model not only significantly reduces human error but also establishes a comprehensive quality control system, ensuring the stability and reliability of every product from the source of production.

WanHai Medical’s strategic plan is already future-focused. Over the next two years, 14 additional intelligent fully automated assembly and inspection production lines will be successively deployed at the production base. By then, WanHai Medical will achieve its strategic goal of an annual production capacity of 400 million units. This will not only accelerate the journey towards import substitution for pen injectors but also, leveraging the advantages of large-scale production, provide global pharmaceutical companies with more cost-effective pen injectors, contributing to the advancement of global healthcare.